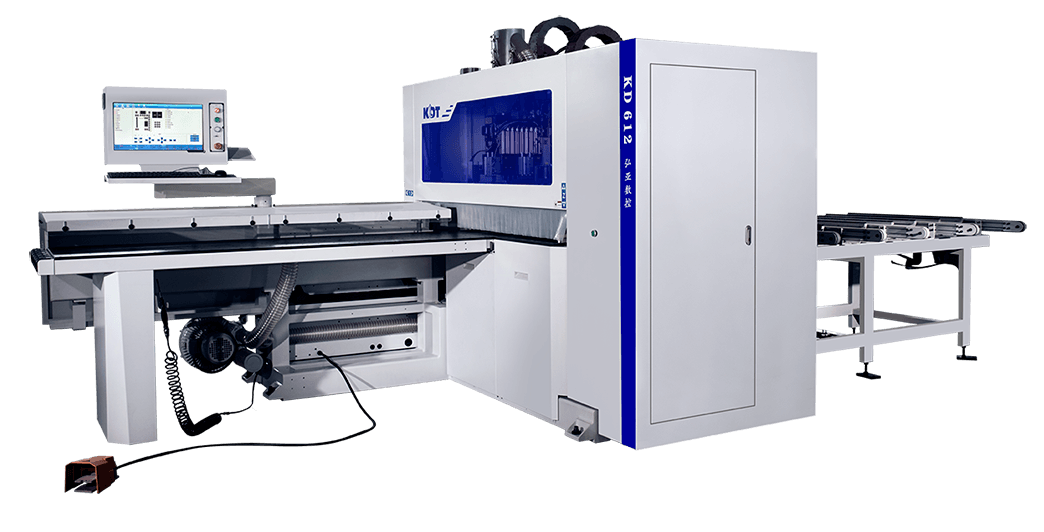

KD-612M

NC boring center, achieve dual working station PTP machine efficiency, single worker operating, small workload, can connect with various disassembly software. Mainly for various man made board six sides boring(hingle hole/through hole/half through hole/horizontal boring), with small spindle can do milling and others.

Detail Information

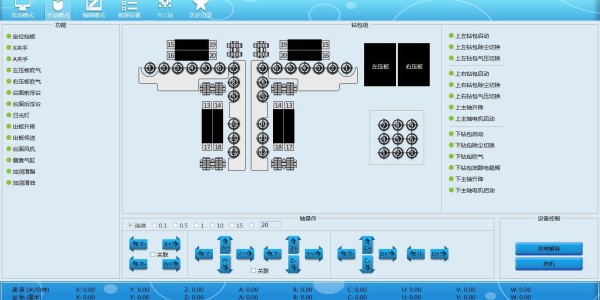

1.Machine scan label to recognize working file, effiency and intelligence;

2.Operating by PC, drawing by CAD, input by CAM, can directly input DXF/MPR/XML etc working format, easy operate;

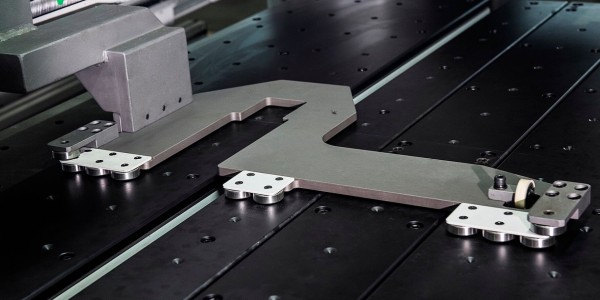

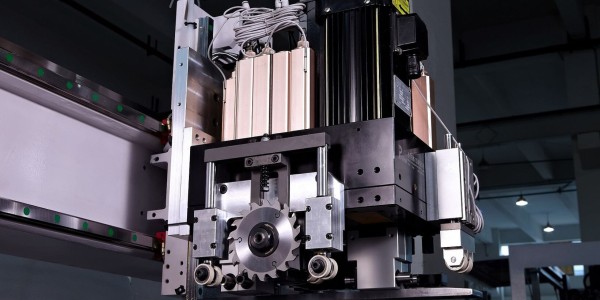

3. With double gripper and long guide rail, gripper speed up to 130m/min, auto detect hole position to avoid gripper exchange time.Gripper trip up to 5.5 meter, big board can working by one time catch, reduce cabinet side board drilling time.

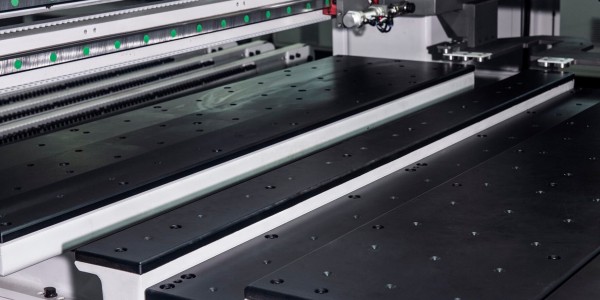

4. With air floating table and press panel, to form air layer at top and bottom side of board during working, improve panel feeding speed and avoid scratch;

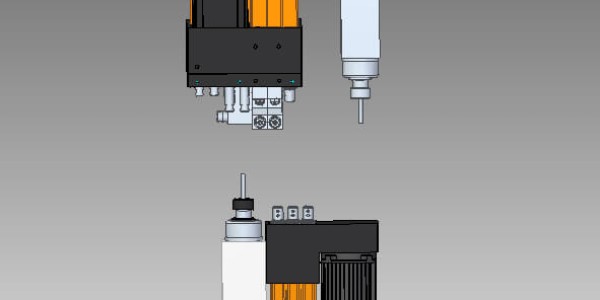

5. Press and drilling at same time, ensure drilling precise and effiency;special drill package position, avoid chip out and error, also avoid dust stach to stuck drill hard.

6. Working model can be select according to production capacity and technology. Have front-in front-out model, good for single worker operating; front-in back-out model good for big production capacity, flexible running and high effiency achieve PTP machine.

CONFIGURATION FEATURES

Technical Specifications

Standard Machine Parameters