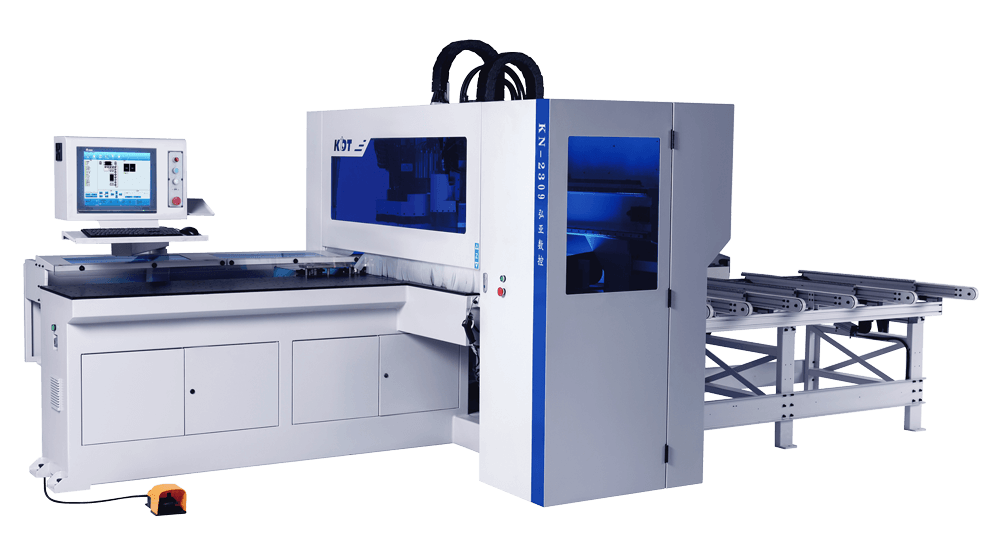

KN-2309T

Application features:

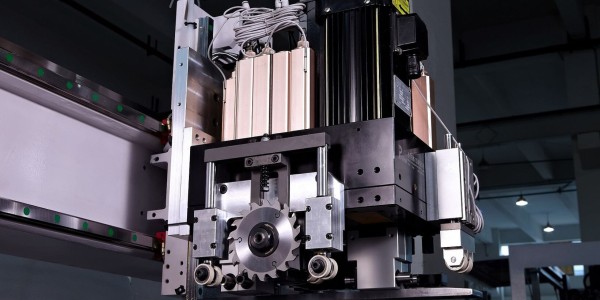

Five-side NC drilling efficiency fully meets the level of duplex PTP processing center, single-person operation, low workload, and can directly dock with a variety of design software. It is mainly used for the vertical (hinge hole, through hole, semi-through hole) and horizontal drilling of all kinds of man-made boards. Standard with 5.5KW spindle, stronger with hogging and milling.

Detail Information

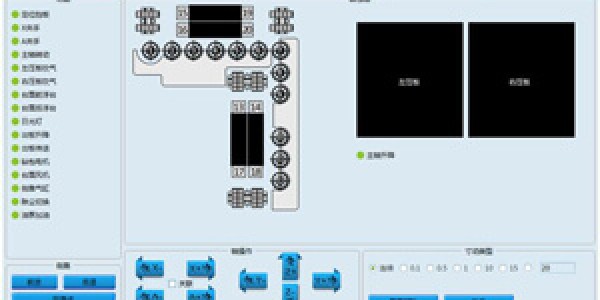

1. The system identifies the processing information by scanning code, which is intelligent and efficient.

2. computer operation, CAD drawing, CAM import, can be directly imported DXF, mpr, XML and other open data formats, easy to operate.

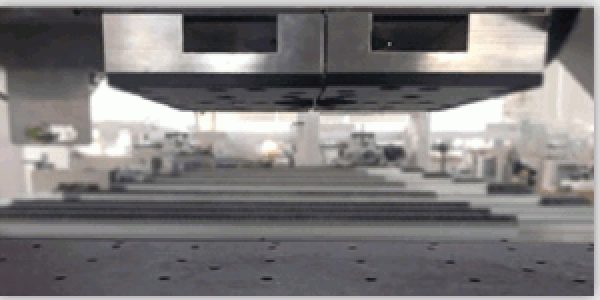

3. With Double gripper guide rail,max moving speed achieve 130m/min, intelligent detection of hole position information effectively avoids the opening position, and reduces the time for changing hands during drilling. The stroke of the gripper is more than 4.4 meters, and the large plates can be grasped at one time. The processing time for drilling the large side plate of the wardrobe is greatly shortened.

4. The structure of the fuselage is unique, and the horizontal hole of multiple sheets can be drilled at one time.

5. Optional processing mode according to production output and production process. After the advancement and exit mode, the lower plate can be processed after the plate is finished. The whole process is smooth and the standby time is short. The forward and backward output modes can be connected and the integrated drilling reaches the level of the imported double-station PTP drilling machining center; The front-out mode is mainly for the case of processing double-sided vertical drilling.

7.5.5KW bigger spindle, stronger and quickly in hogging and milling.

CONFIGURATION FEATURES

Technical Specifications

Standard Machine Parameters