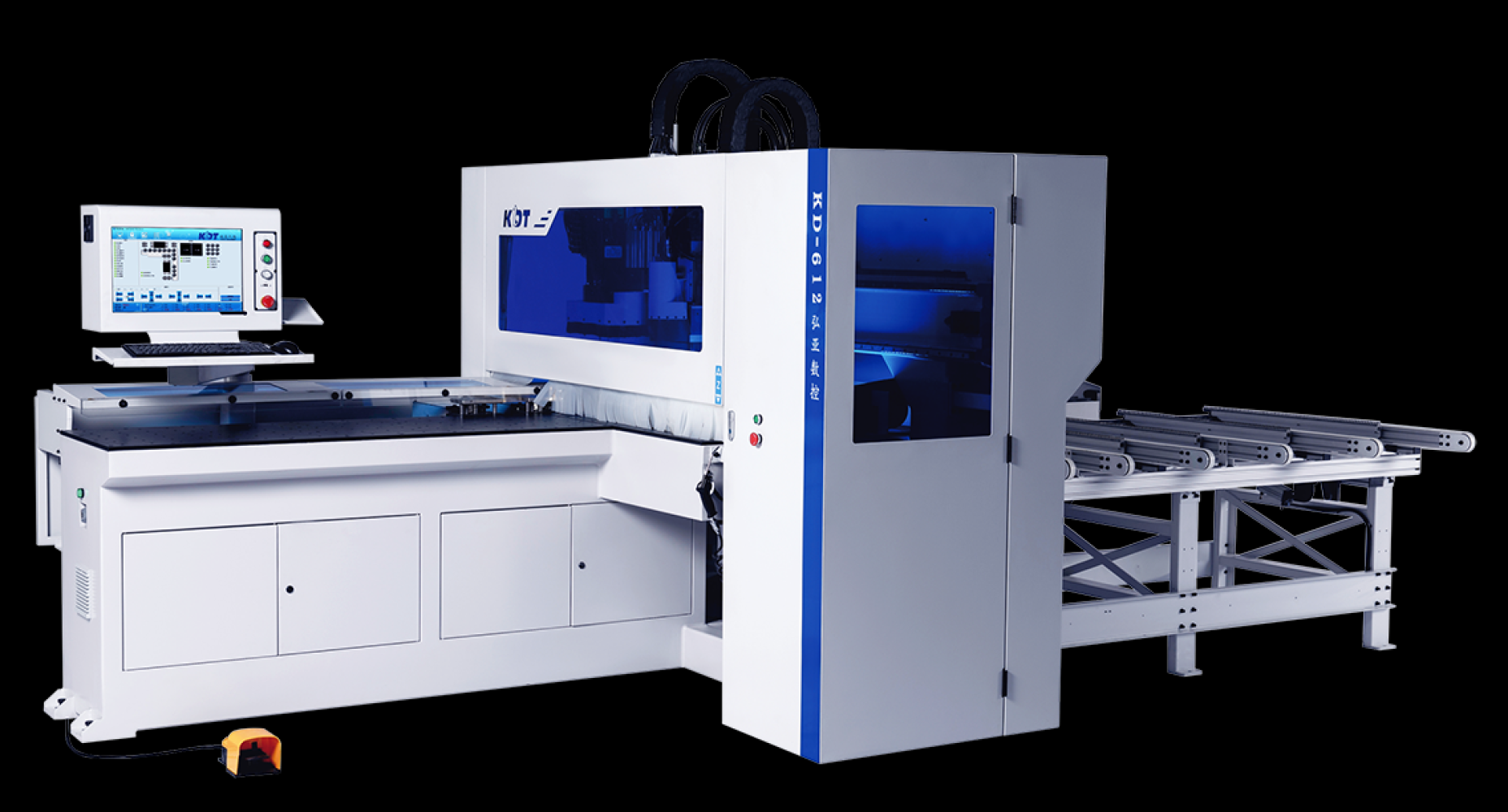

KD-612

Six Sides Drilling Machine

There is Best for everything.

WANT MORE INFO?

SEE THIS MACHINE Distinctive features

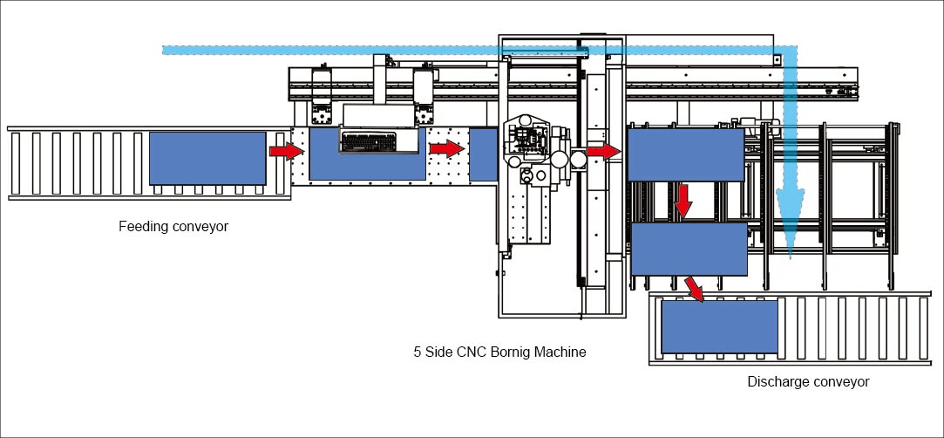

NC Boring center, six sides drilling machine, 2 working stations, single-person operation, small workloads, can connect with variety disassemble software. Mainly used for six sides holes, if with spindle can groove and router.

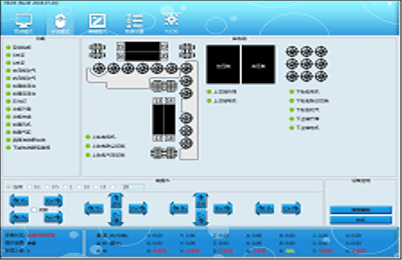

- Recognize work processing information by scan. Intelligent and efficient.

- PC control with CAD/CAM.DXF/MPR/XML data can be imported directly. More convenient operation.

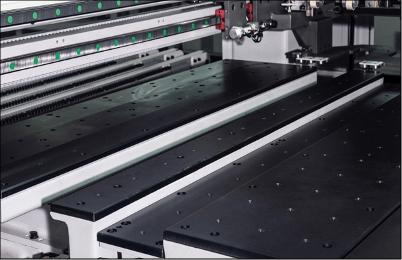

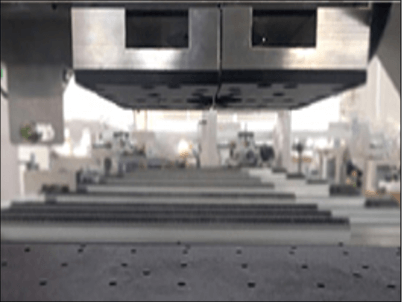

- Double gripper rail, the max speeding can reach 130/min. Intelligent detection of hole position, the gripper can travel more than 4.4m and can get large board one time.

- Air floating table and pressure beam to avoid the board scratch.

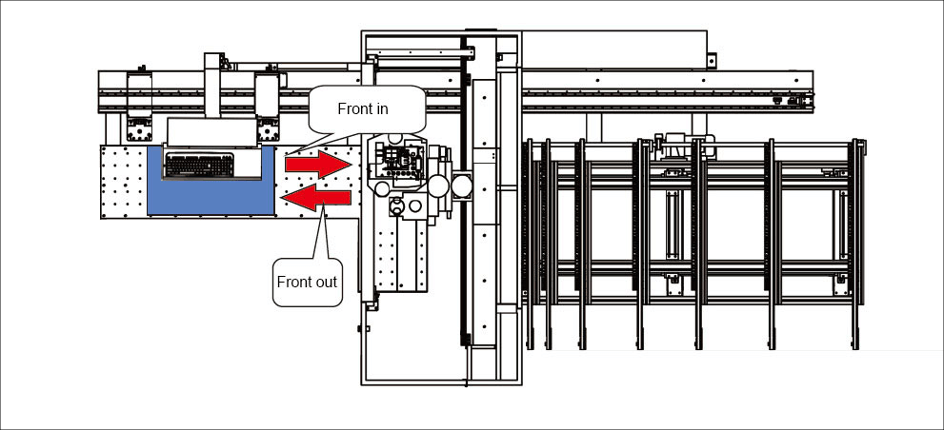

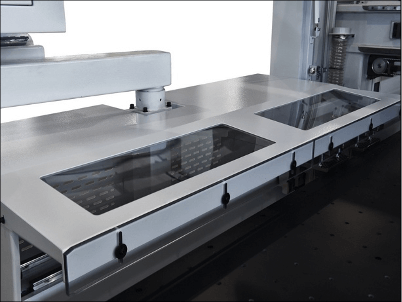

- Optional feeding mode: front-in & out/ front-in & back-out

Features

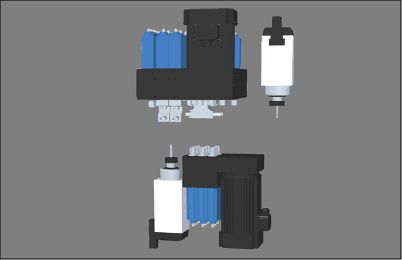

Standard: top drill package: 12V+4H, bottom drill package: 9V

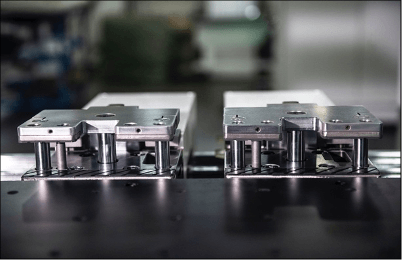

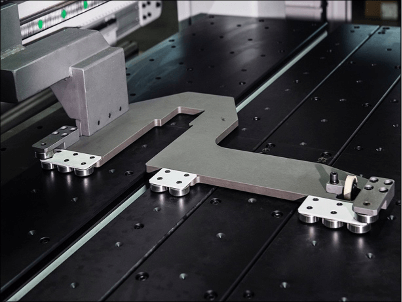

Lifting table, can move up and down/left and right, reduce panel scratch and hit

Double gripper and long rail, quickly process all kinds of panel drilling

Computer control+CAD/CAM, easy to operate

Side aligner and floating table, ensure processing precise, avoid panel scratch

Floating table and press beam work together to fix panel when processing, avoid panel scratch

Safety unit: With gripper cover, safety operating

Scan label to processing (scan gun free)

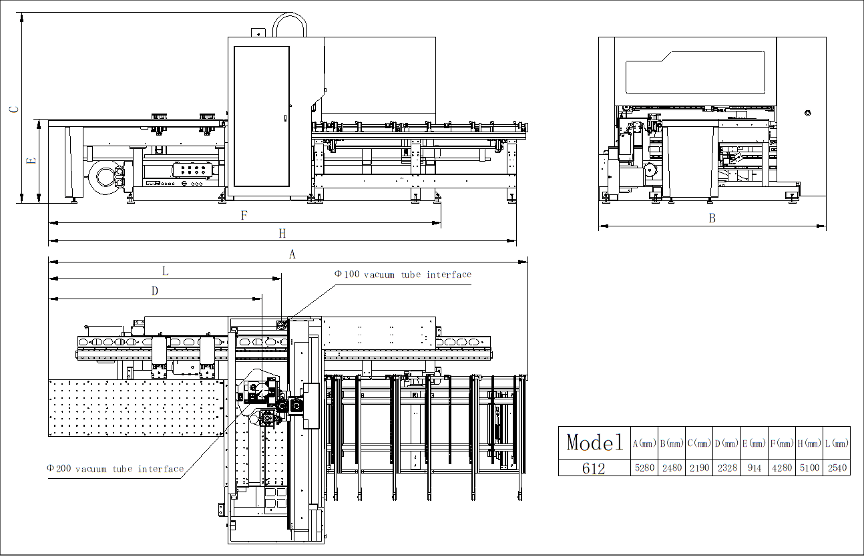

Layout Dimension

Standard Machine Parameters

Size: 5200mm x 2300mm x 2350mm

Gross Weight: 2970 Kg

Power: 20.65 kW

Working Pressure: 0.6 MPa

Applications

Front in rear out, high efficiency. When machine work with one panel, operator can scan other panel's message and make whole working process fluent.